American Indians and Alaska Natives (AI/AN) carry an extensive legacy of trading foods between their people and amongst tribal nations. The ability to bring foods into commerce, whether for trade or purchase, has been a meaningful way for building relationships and strengthening the resilience of their economies based in food systems. Today’s economies and how operations are structured may have adjusted over the years due to colonialism and other factors, but the production and marketing of food products is just as important.

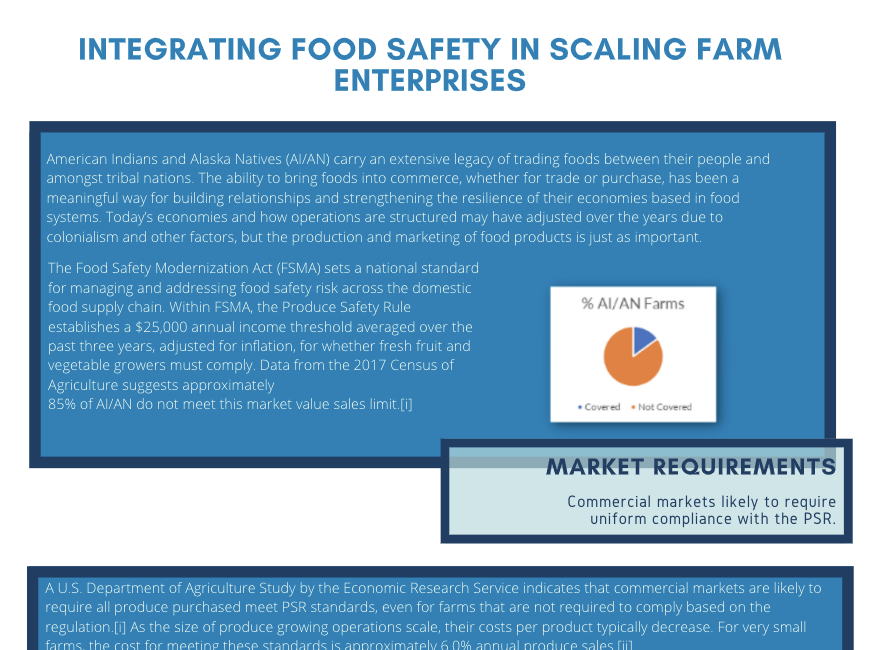

The Food Safety Modernization Act (FSMA) sets a national standard for managing and addressing food safety risk across the domestic food supply chain. Within FSMA, the Produce Safety Rule establishes a $25,000 annual income threshold averaged over the past three years, adjusted for inflation, for whether fresh fruit and vegetable growers must comply. Data from the 2017 Census of Agriculture suggests approximately 85% of AI/AN do not meet this market value sales limit.[i]

MARKET REQUIREMENTS

Commercial markets likely to require uniform compliance with the PSR.

A U.S. Department of Agriculture Study by the Economic Research Service indicates that commercial markets are likely to require all produce purchased meet PSR standards, even for farms that are not required to comply based on the regulation.[i] As the size of produce growing operations scale, their costs per product typically decrease. For very small farms, the cost for meeting these standards is approximately 6.0% annual produce sales.[ii]

Integrating food safety practices from the start allows farms to set a solid foundation for expectations, both for the primary decision-makers and those that support them.

6% ANNUAL PRODUCE SALES

Compliance Cost for Very Small FarmsINFRASTRUCTURE CONSTRAINTS

Farms can integrate food safety practices in all environmentsWORKER TRAININGS

Workers must be trained annually, but retraining on new food safety practices is more challengingFOOD SAFETY

Navigating post-colonial food safety recognizes the need for strategic actions

BUDGET AND INFRASTRUCTURE FRIENDLY CONSIDERATIONS FOR FOOD SAFETY IN INDIAN COUNTRY

HARVEST BINS & BASKETS

Can be reusable or single-use. If using a reusable bin, make sure they are cleaned & then sanitized between each use

RECORDKEEPING

Can be electronic or paper but must be available to all areas of an operation so events can be logged in real time. Records must generally be kept for 2- years.

PACKING HOUSES

Do not need to have 4 walls or a roof.No matter what the layout, take steps to prevent rodents, pests, and other contamination, e.g., wind drift

TRUCKS, INCLUDING PICK-UPS

Can be used for multiple purposes. Make sure they are cleaned before hauling produce. A clean liner may be used as a barrier if it prevents contamination.

PORTA-POTTIES

If used, should be kept away from and not up-hill from growing areas with a point of contact on speed dial in case of tipping or seepage. Remember, OSHA requires 1 toilet for every 20 workers within ¼ mi. of the work area.

COLD STORAGE AND ICE BATHS

Are not required but do help preserve shelf life for fresh produce. If using these areas, monitor regularly to ensure they are working properly, e.g., no leakage.

TOOLS & EQUIPMENT

Can be used in multiple areas of the operation as necessary. Make sure that they are thoroughly cleaned and sanitized between uses.

HAND-WASHING STATIONS

Can be used instead of sinks where plumbing is not readily available near toilet facilities or growing areas. Hand-washing stations can be outside and, if used, must have the following Elements:

- Enclosed, Clean water jug with spigot faucet (not a push button).

- Liquid (preferred) or bar soap

- Single use paper towels on a roll

- Catch Basin under faucet to contain grey hand-wash water

- trash can

Remember, OSHA requires 1 hand-wash station for every 20 workers within ¼ mi. of the work area.

“2017 CENSUS OF AGRICULTURE: RACE/ETHNICITY/GENDER PROFILE,” USDA NATIONAL AGRICULTURAL STATISTICS SERVICE (OCTOBER 1, 2019), SEE: COMPLETE PROFILE FOR ENTIRE UNITED STATES, VIEWABLE AT HTTPS://WWW.NASS.USDA.GOV/PUBLICATIONS/AGCENSUS/2017/INDEX.PHP.

TRAVIS MINOR, ET AL., “FOOD SAFETY REQUIREMENTS FOR PRODUCE GROWERS: RETAILER DEMANDS AND THE FOOD SAFETY MODERNIZATION ACT,” ECONOMIC INFORMATION BULLETIN, NO. 206, USDA ECONOMIC RESEARCH SERVICE (APRIL 2019), HTTPS://WWW.ERS.USDA.GOV/WEBDOCS/PUBLICATIONS/92761/EIB-206.PDF?V=10.4.

JOHN BOVAY, PEYTON FERRIER, AND CHEN ZHEN, “ESTIMATED COSTS FOR FRUIT AND VEGETABLE PRODUCERS TO COMPLY WITH THE FOOD SAFETY MODERNIZATION ACT’S PRODUCE SAFETY RULE,” ECONOMIC INFORMATION BULLETIN, NO. 195, USDA ECONOMIC RESEARCH SERVICE (AUGUST 2018), HTTPS://WWW.ERS.USDA.GOV/WEBDOCS/PUBLICATIONS/89749/EIB-195.PDF?V=0.